Following processes are Outsourced to carefully Selected Suppliers:

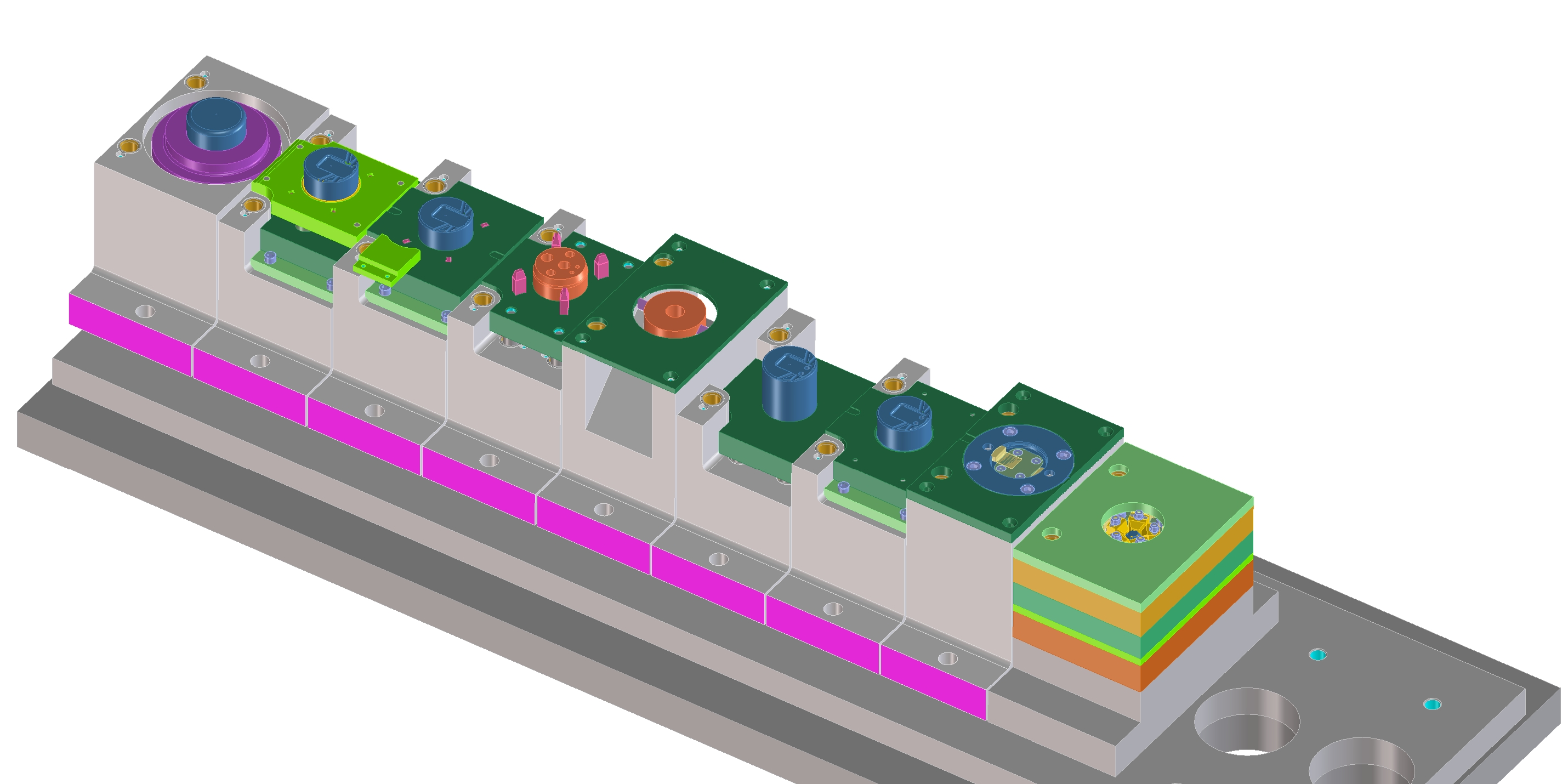

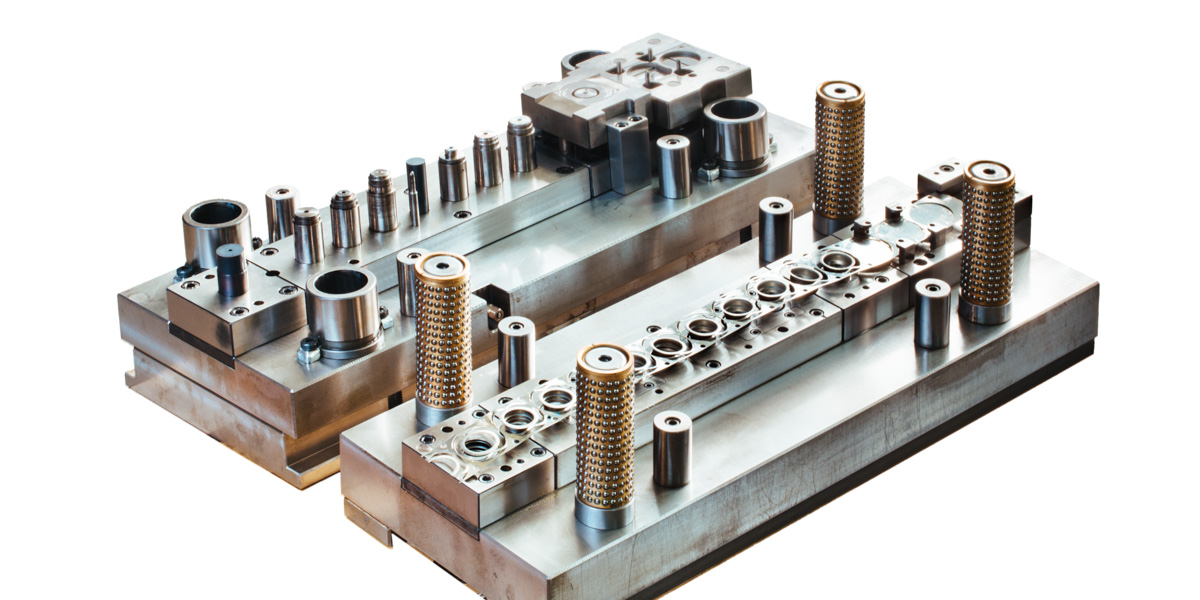

– Mass production Tooling Design and Construction (Toolmaker). Tooling is that device that installed on a mechanical press machine shapes the raw material and so permit to obtain the desired part in a repetitively manner, that means it has a key role on Metal Stamping Process. During Feasibility Study and Project Definition phase of a Customer’s Project, we identify which is the best solution in terms of kind of tooling to work with; VE-CA have gained a robust experience working with the following type of tooling: Single Step tooling, Progressive Die tooling and Transfer tooling, for each of those, we can choose from a shortlist of at least two consolidated local Suppliers.

Once selected the Supplier, VE-CA set the Requirements and with those, the Toolmaker can start Tooling Design, at the end of which (before starting tooling construction), a Review activity is performed in order to make sure all Requirements are met.

At the end of Tooling Construction, Supplier provides Tooling Project Documentation together with First Samples produced with, all that material is then examined and filed by VE-CA.

Finally, the tooling is tested in our facility under real conditions of use for PPA purposes.

– Galvanic and Heat Treatment. Some products after stamping are required to be heat or galvanic treated, for each, we have a shortlist of selected local Suppliers.

Galvanic treatments such Chrome/Nickel/Tin/Zinc/Zinc-nickel Plating, Passivation, Electro-polishing are common on our products. Most of our Suppliers are equipped to perform Coating Thickness Analysis, Salt Spray Test and provides Certificate of Conformity upon request.

Heat treatments such Austempering, Carbonitriding, Stainless Steel/Brass Annealing are common on our products. For stainless steel annealing our Suppliers are equipped with latest Hydrogen controlled atmosphere Continuous Furnaces. All Suppliers who perform heat treatments are equipped to perform Hardness Test and provides Certificate of Conformity at each delivery.

– Packing. Normally our parts are supplied in bulk into standard cardboard boxes. Some Customers requires their products to be supplied in a specific way (e.g. parts counted and packed into customized plastic bag and in turn packed into customized cardboard boxes or customized boxes with interlayers and/or corrosion protection paper to protect the content), in that case we outsource the process to selected local Supplier.

VE-CA’s Direct Material Purchasing mainly includes Metal Coil Strips.

We yearly purchase approximately 500T of metal coil strips – different types, grades and physical status, the raw materials are sourced within Europe, mainly directly from the Mills. Those mills comply with latest REACH, ROHS and Conflict Minerals Regulations. EN 10204 3.1 Raw material Certificates are supplied at each delivery; periodically, the raw material supplied, is analyzed by an accredited Third-Party Lab. for certificate crosscheck purposes and more generically, to ensure that the raw material supplied, comply with our Requirements in terms of Grade/Chemical Composition and Mechanical Characteristics.

Raw materials such Stainless Steel AISI 301, AISI 304, AISI 305, AISI 316, AISI 420 grades, Brass OT 63 and OT 67 are commonly purchased by us.

Deutsch

Deutsch